1997 Honda 750 Nighthawk

«

^

»

Work log on Frankenhawk

Update June 8 2009

Here's my latest update. With pics this time. First 6 are dated closer to the last page. The others were taken after her maiden voyage.

Mm-mm-mm. Two-wheeled goodness. Been off bikes too long and I really missed it.

Didn't make the birthday ride because, after I dressed her and put her in the driveway, I couldn't keep her running. Slowly died out over about a minute or so. Wouldn't start after that. Seemed like no gas was getting to it. Figured there was some problem with the vacuum diaphrahm since Frankie worked fine on the test tank.

Didn't get back to it until Friday. Put the test tank on...she ran fine. Yup, gotta be that diaphrahm.

Was all set to bypass the vacuum part until I noticed I had turned off the fuel. That's right, with my years of bike experience and some mechanical aptitude, I had set the petcock to the "OFF"position.

Aaighhhh!

I went ahead and tore the petcock apart for a cleaning while I was there because it needed one anyway. Yeah, I meant to do that.

Of course she started right up after that. And I put the Acewell on before I re-dressed her, since I had it, and took my weekend test ride. It's only working for the tach and shows double what the bike is running. I'll have to adjust it.

|

Here's a "from the rear" view. Shows the original tach installed, the new (to me) headlight, and the Interceptor mirrors. |

And this is the universal headlight bucket with 41mm fork brackets and mini-turn signals. Went on easily. Once the Acewell is on I will probably move the fork clamps up. Right now they're at 100mm from the top clamp.

Not really sure I like the mini signals. To my eye they're just way to small. |

|

|

Oh, yeah. My fancy rebuild job on the rear cowling. I think that strapping across the back shows the how I think at the peak of my mechanical skills.

It was that or duck tape. And it may still be...although I don't have any duck tape, I have gorilla tape.

Supposed to be stronger...and it's black.

The wiring you see is for the left signal. Made the leads a little long. |

I guess the shade-tree build is not that noticable from the back. It's all there and the tail light stays where it is supposed to be. The rear signals—taken from the Interceptor—look good actually. Their proportions look right for that backend.

For those paying attention to background details, the wire you see is an extension cord for the battery minder. Since I didn't know how long she'd sit before first run, I put it on to float a charge. |

|

|

This pic doesn't really show enough detail, but it does show the proportions that make it work. |

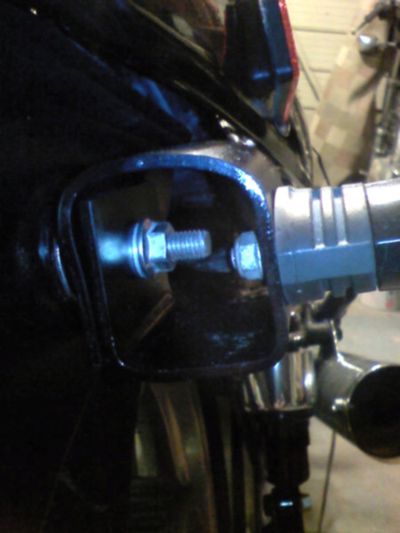

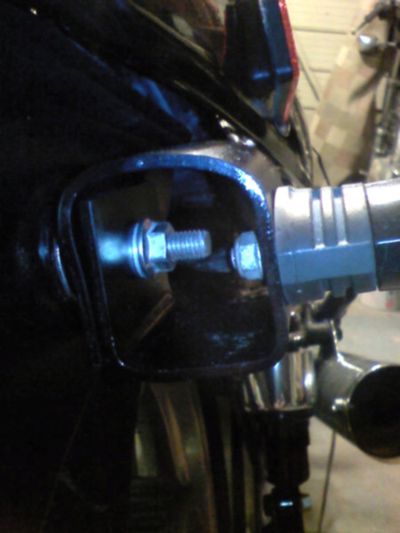

Here's a better detailed pic of one of the brackets I made. Very simple. Does the job. And the black paint job hides my crap fab job. Isn't as obvious as a $16 dollar bill. |

|

|

Here we are last night. I've got the ignition on so the Acewell lights up. Small but covers all the functions I want...or need.

Don't like the mount though. The angle is too sharp and when riding, most of what I see is a reflection of the handlebars. Needs to bend back about 20°.

Instead of bending the very heavy mounting bar that's on it, I'll make up a bracket from flat stock that uses both mount holes. I can also use one to put the gauge more in the center.

The blue and red wires are there because I ran them in preparation for the horns. Couldn't use local power so I've tapped the battery directly. |

| Side view of how the gauge sits. Needs a minimum of 20°...may need 30° or more. I'll play with it. |

|

|

Front right pic of Frankenhawk dressed...well except for the headlight. This is her better side. And is also the side for the cover I bought. |

I found this set of 110dB horns by Rede at Harbor Freight for $10. The only problem (for me) was they were chromed. That'll make them stand out like a neon sign. |

|

|

Fixed. Couple of blasts of black satin-finish spray and we're ready.

I'm going to use the mount bars that came with them, twisted 90°, and thrown on the headlights fork clamp through bolt.

If that doesn't work I'll fab a bracket that mounts on the lower fork clamps. |

So what's next? Speed detection and horns. Then insurance, tags, and inspection. Add gas and enjoy.

I had to get the Acewell speedo cable for generic use. Magnet-head bolt and hall-effect sensor. But the bolt won't fit on the brake rotor anywhere—their recommended mount point. Bolt head hits the forks; too tight a clearance.

I'm looking at putting it on a home-made bracket bolted through one (or more) of the driven sprocket bolts. I'll also have to make the sensor wire longer because of that.

«

^

»

You are vistor